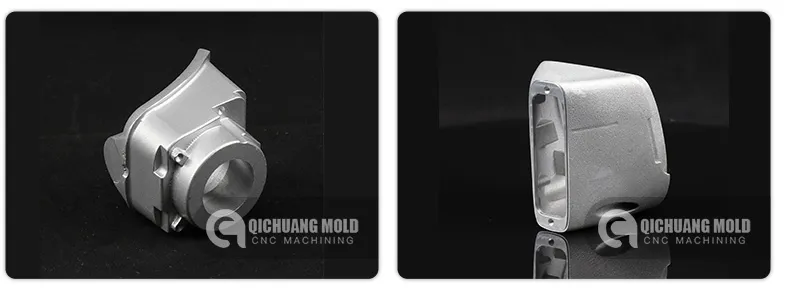

What is a Diecast Part?

Diecast parts are components manufactured using a die casting process, where molten metal is injected under high pressure into a mold cavity. This method allows for the creation of intricate and complex shapes with tight tolerances, making it a preferred choice in various industries. The process results in high-quality parts with excellent surface finishes and dimensional accuracy. Diecasting is particularly advantageous for producing a large volume of parts efficiently and cost-effectively. From automotive components to consumer electronics and aerospace parts, diecast components play a crucial role in modern manufacturing.

The Diecasting Process

The die casting process involves several key steps. First, a die, typically made of steel, is created to form the desired shape of the part. Molten metal, such as aluminum, zinc, or magnesium, is then injected into the die cavity under high pressure. This pressure ensures that the molten metal fills every detail of the mold. Once the metal cools and solidifies, the die is opened, and the part is ejected. The process is highly automated, allowing for rapid production cycles. After ejection, the parts may undergo secondary processes such as trimming, machining, or surface finishing to achieve the final product specifications.

Materials Used in Diecasting

A variety of materials can be used in the die casting process, each offering unique properties. Aluminum is a popular choice due to its lightweight, high strength-to-weight ratio, and excellent corrosion resistance. Zinc is another widely used material, known for its good castability, dimensional stability, and ability to produce thin-walled parts. Magnesium is favored for its lightweight properties and excellent machinability. Other materials, such as copper alloys and lead-based alloys, are also employed depending on the specific application requirements. The selection of the appropriate material depends on factors like mechanical properties, operating environment, and cost considerations.

Top 7 Amazing Benefits of Diecast Parts

Benefit 1 High Precision and Accuracy

Die casting enables the production of parts with exceptional precision and accuracy. The high-pressure injection of molten metal into the die cavity ensures that the part conforms exactly to the mold’s dimensions. This results in tight tolerances and consistent dimensions, essential for applications where precise fits and functionality are critical. This precision minimizes the need for secondary machining operations, thereby reducing both production time and costs.

Benefit 2 Complex Geometries and Designs

Die casting excels in producing parts with intricate geometries and complex designs that would be difficult or impossible to achieve with other manufacturing methods. The process can create thin walls, sharp corners, and fine details, allowing for the integration of multiple features into a single part. This design flexibility is a major advantage, enabling engineers to create highly functional and efficient components, improving product performance and aesthetics.

Benefit 3 High Production Volumes

Die casting is highly efficient for mass production. The automated nature of the process allows for rapid cycling times, leading to high production volumes in a relatively short period. This is especially beneficial for industries that require a large number of identical parts, such as automotive, consumer electronics, and appliance manufacturing. The ability to produce parts quickly and efficiently reduces lead times and lowers the overall cost per part.

Benefit 4 Excellent Surface Finish

Die-cast parts typically exhibit a superior surface finish, often requiring minimal post-processing. The smooth surface is a result of the molten metal’s interaction with the die. The quality of the surface finish can improve aesthetics, reduce friction, and enhance corrosion resistance. Furthermore, this smooth surface makes the parts more suitable for subsequent finishing operations like painting, plating, or powder coating, providing versatility in design and functionality.

Benefit 5 Material Variety and Selection

Die casting can accommodate a wide range of materials, including aluminum, zinc, magnesium, and copper alloys. Each material offers unique properties that can be tailored to the specific requirements of the application. The choice of material allows engineers to optimize for factors such as strength, weight, corrosion resistance, and thermal conductivity. This flexibility in material selection makes die casting suitable for diverse industries and applications.

Benefit 6 Enhanced Strength and Durability

Die-cast parts generally possess high strength and durability due to the rapid solidification process and the dense structure of the material. This makes them capable of withstanding significant mechanical stress and harsh environmental conditions. This is particularly important in applications where the parts are subject to heavy use or exposure to elements. The enhanced strength and durability contribute to a longer product lifespan and improved reliability.

Benefit 7 Cost-Effectiveness

Die casting can be a cost-effective manufacturing method, especially for high-volume production runs. The automated nature of the process and the minimal need for secondary machining operations help to reduce labor costs. While the initial cost of creating the die can be significant, the cost per part is generally lower than other manufacturing processes, making it a cost-effective solution for producing large quantities of components.

Applications of Diecast Parts

Automotive Industry

The automotive industry is a major user of die-cast parts, with applications ranging from engine components and transmission housings to chassis parts and interior components. The high strength-to-weight ratio of die-cast aluminum makes it ideal for reducing vehicle weight while maintaining structural integrity. Die casting’s ability to produce complex geometries and high volumes makes it perfect for the automotive sector.

Consumer Electronics

Die-cast parts are widely used in consumer electronics, including laptops, smartphones, and gaming consoles. These parts provide structural support, heat dissipation, and electromagnetic shielding. The ability to create intricate designs and high-quality surface finishes is particularly important in this industry, as aesthetics and functionality are key considerations.

Aerospace Industry

The aerospace industry utilizes die-cast parts for a variety of applications, including aircraft engine components, structural parts, and interior components. The high strength-to-weight ratio and dimensional accuracy of die-cast parts are critical in this industry, where performance and reliability are paramount. The ability to withstand extreme temperatures and stresses makes die casting a valuable process for aerospace applications.

Tips for Choosing Diecast Parts

Consider the Material

When selecting die-cast parts, it is crucial to consider the material properties. Factors such as strength, corrosion resistance, thermal conductivity, and cost should be evaluated based on the intended application. Ensure the chosen material meets the required performance specifications and environmental conditions.

Assess the Design Requirements

The design of the part is a key factor. Consider the complexity of the geometry, the required tolerances, and any specific features that must be incorporated. The design must align with the capabilities of the die-casting process. It is important to consult with a die-casting expert to ensure the design is optimized for manufacturability.

Evaluate the Production Volume

The volume of production is a critical determinant of die casting feasibility. Die casting is most cost-effective for high-volume runs. Assess the anticipated production quantities to determine if die casting is the appropriate manufacturing method. If the volume is low, other methods like CNC machining might be more economical.

Diecast Parts Future Trends

The future of die-cast parts includes advances in materials, processes, and automation. New alloys, such as those that are lighter and stronger, continue to emerge. More efficient die-casting processes, including those that minimize waste and energy consumption, are also in development. Integration of advanced technologies, such as digital manufacturing and AI, will drive further improvements in precision, efficiency, and design flexibility, ensuring die-cast parts remain at the forefront of manufacturing.