Disassembling diecast cars can be a rewarding hobby, whether you’re aiming to restore a classic model, customize a car to your liking, or simply understand how these miniature vehicles are constructed. The process can seem daunting at first, but with the right tools and a methodical approach, you can take apart diecast cars with ease. This guide provides a comprehensive overview of how to disassemble diecast cars, covering everything from essential tools to step-by-step instructions and important reassembly tips. The satisfaction of bringing a diecast car back to its former glory, or customizing it to your vision, is a hobby that will surely bring joy.

Tools You’ll Need to Disassemble Diecast Cars

Before you begin disassembling a diecast car, gathering the appropriate tools is crucial for a smooth and damage-free process. Using the wrong tools can lead to stripped screws, broken parts, and frustration. This section outlines the essential tools required, emphasizing their importance and offering insights into choosing the right equipment. Investing in quality tools upfront will not only simplify the disassembly process but also protect your diecast models from potential damage.

Screwdrivers and Their Role

Screwdrivers are the workhorses of diecast car disassembly. You’ll need a set of precision screwdrivers, including Phillips head and flathead options, in various sizes. Diecast cars often use tiny screws, so having a range of sizes ensures you can handle any model. A magnetic screwdriver can be particularly helpful for holding screws in place, preventing them from getting lost. Consider investing in a screwdriver set specifically designed for small electronics or model building, as these often include the necessary sizes and types.

The Importance of Prying Tools

Prying tools are essential for gently separating components without causing damage. These tools are typically made of plastic or nylon to avoid scratching or marring the diecast metal. A set of plastic pry bars or spudgers in different shapes and sizes will be incredibly useful for removing wheels, interiors, and body components. Use these tools to carefully lever apart parts that are glued or snapped together. Patience and a gentle touch are key when using prying tools to avoid bending or breaking delicate parts. The use of prying tools reduces the chances of damaging the car during disassembly.

Additional Tools for Specific Tasks

In addition to screwdrivers and prying tools, other tools can make the disassembly process easier. A hobby knife or X-Acto knife can be used to carefully cut away glue or release tabs. Small pliers or tweezers are useful for gripping and manipulating tiny parts. A magnifying glass can help you see small details and screws, especially on older or more complex models. Finally, a well-lit workspace is crucial. Good lighting will allow you to see all the parts and any hidden screws or clips you need to remove. Having these tools readily available will significantly improve the disassembly experience.

Step-by-Step Guide to Disassembling Diecast Cars

With your tools assembled, you are now ready to start disassembling your diecast car. This section provides a detailed, step-by-step guide to take apart diecast cars safely and efficiently. Following these steps will help you avoid common pitfalls and ensure you can successfully reassemble your model. Remember to work slowly, pay attention to detail, and keep track of the parts as you remove them.

Preparing the Car for Disassembly

Before you begin, examine the car carefully. Note any visible screws, clips, or glued parts. Take pictures of the car from various angles before you start disassembling it, to serve as a visual reference during reassembly. Place the car on a clean, well-lit workspace. Gather all the tools you need within easy reach. This preparation will help you stay organized and make the disassembly process much smoother.

Removing the Wheels

Wheels are usually the first components to be removed. In many diecast cars, the wheels are held in place with axles that can be pulled out using pliers or tweezers. Some models may have the wheels pressed in, and you might need to carefully pry them out with a small prying tool. Be gentle when removing the wheels to avoid bending the axles or damaging the wheel hubs. Place the wheels in a safe place to prevent them from getting lost.

Detaching the Chassis from the Body

Once the wheels are off, the next step is to separate the chassis from the body. This is usually done by unscrewing screws on the underside of the car. Locate all the screws that attach the chassis to the body and remove them using the appropriate screwdriver. If the chassis doesn’t separate easily, check for any hidden screws or clips. Sometimes, the chassis is glued to the body. In this case, you will need to use a prying tool to gently separate the two parts, working slowly around the perimeter to avoid bending or breaking anything.

Disassembling the Interior Components

With the chassis and body separated, you can now proceed to disassemble the interior components. The interior often consists of a dashboard, seats, steering wheel, and other details. Carefully examine how these parts are attached. Some may be held in place by screws, while others may be clipped or glued. Use the appropriate tools, such as small screwdrivers or prying tools, to detach these components. Be mindful of small pieces that can easily be lost. Have a container on hand to keep all the pieces together.

Body Component Removal

Finally, you can remove the body components, such as the windows, mirrors, and other external details. These are usually attached using clips, glue, or small screws. Use a prying tool to carefully separate these components. Be extra cautious when removing windows, as they can be fragile. Keep all the parts in a safe place, noting where they came from. If there are any decals, take photos before removing them to use as a reference later.

Reassembly Tips and Considerations

Taking apart a diecast car is only half the battle; reassembling it correctly is equally important. This section offers essential tips and advice for successful reassembly, addressing common challenges and providing guidance to help you restore your model to its former glory. Following these guidelines will improve your chances of a positive outcome.

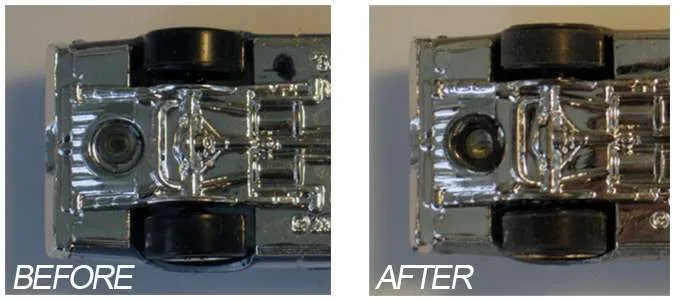

Cleaning and Lubrication

Before reassembly, clean all the parts thoroughly. Use a soft cloth and mild soap to remove any dirt or debris. For stubborn grime, you can use isopropyl alcohol. Make sure all parts are completely dry before reassembling. If you are restoring an older model, consider lubricating the axles and moving parts with a small amount of model-specific lubricant. This will help the wheels spin smoothly and prevent friction. Applying a small amount of lubricant to the moving parts can dramatically improve their performance.

Reassembly Order and Tips

When reassembling, follow the reverse order of the disassembly process. Start with the interior components, then attach the body to the chassis. Reinstall the wheels last. Refer to your pictures or the original model to ensure each part is correctly positioned. Don’t overtighten screws, as this can strip the threads or damage the parts. If you encounter difficulty, double-check your references and make sure all parts are correctly aligned. Take your time and enjoy the process of putting your diecast car back together.

Avoiding Common Mistakes

Several common mistakes can complicate the reassembly process. Losing small parts is a frequent issue, so be sure to work in a clean, well-lit area and use a container to hold all the parts. Stripping screws is another common problem. Use the correct screwdriver size and don’t force the screws. Avoid using excessive force, which can lead to broken parts. Finally, rushing the process often leads to mistakes. Take your time, be patient, and double-check your work at each step. These precautions will help you avoid many of the common pitfalls.

Customization and Further Steps

Once you have mastered the art of disassembling and reassembling diecast cars, you can explore many other possibilities. You can customize the car by repainting the body, adding new details, or modifying the chassis. You can also restore damaged models, replacing missing parts or repairing broken components. The world of diecast cars offers endless opportunities for creativity and enjoyment. Further research into various customization techniques can help you take your hobby to the next level.

Taking apart diecast cars is a detailed process requiring patience, the right tools, and a methodical approach. By following the steps outlined in this guide, you can successfully disassemble and reassemble diecast cars. Whether you are restoring a classic, customizing a model, or simply enjoying the hobby, the satisfaction of working with these miniature vehicles can be immense. With each project, you will gain experience and refine your skills. Happy dismantling and enjoy your journey into the world of diecast cars!